Brew Guide:

Best Brewed with: Espresso, Moka Pot, French Press

Medium-Heavy Roaster Influence:

Roasted for solubility & balanced acidity (E.A. decaf can be intensely tropical!) and texture.

Best rested: 1-2 weeks

For Filter: We recommend a ratio of 65g/L and 90°C water

For Espresso: 18g in, 40g out, 28-32s for a classic style of espresso.

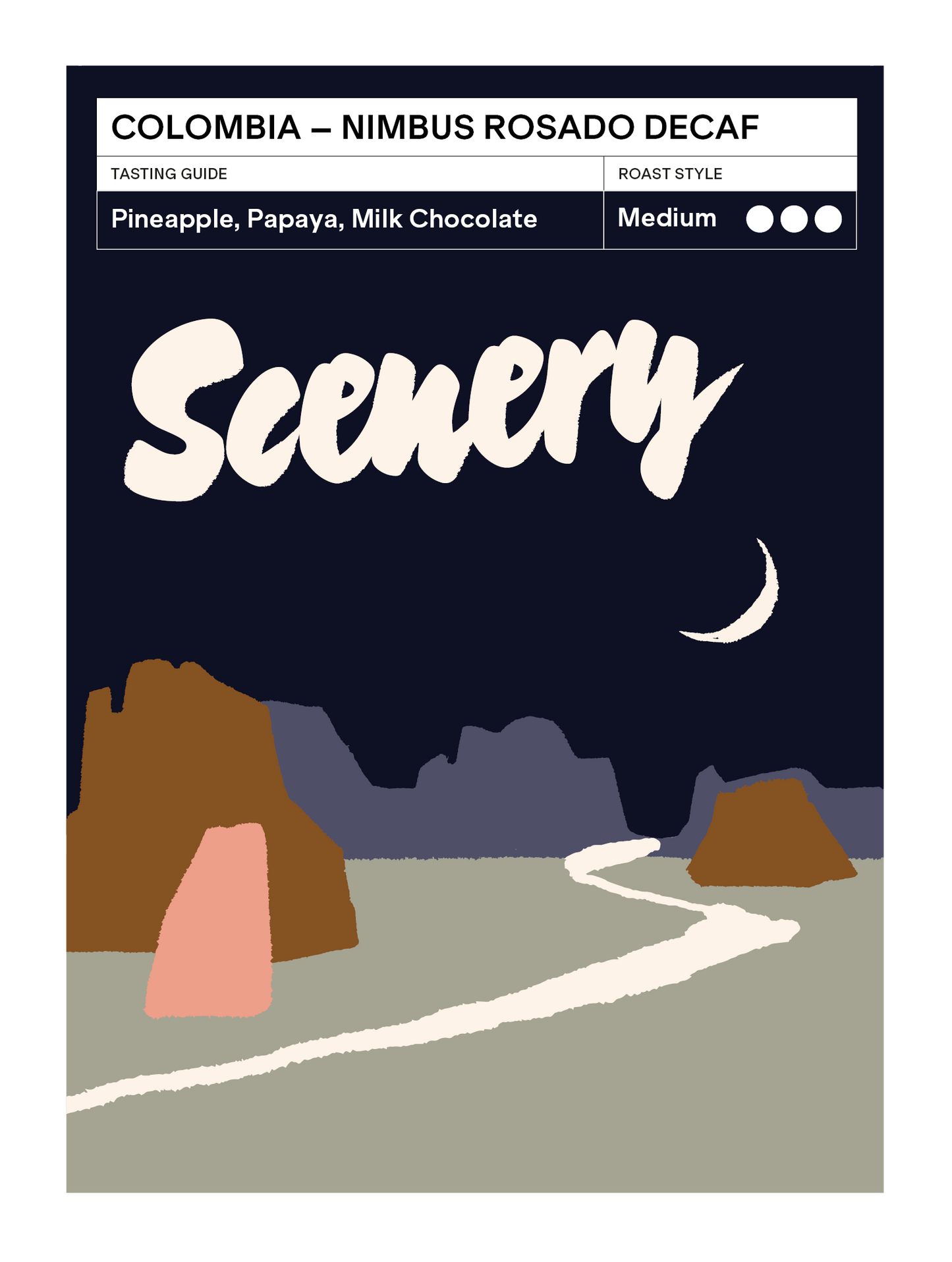

We're tasting: Pineapple lumps, tropical fruit drops, ripe papaya, madeira sherry, milk chocolate

In milk: Baba au rhum & marzipan

Please note - due to the nature of the physiochemical changes undergone during the decaffeination, this coffee will visually appear to be a darker roast than its actual “perceived” roast degree

Traceability:

The Story:

We've worked with Raw Material for several years now, their "maximum impact coffee" philosophy aligns with our sourcing program intentions. They operate as a Community Interest Company, returning 100% of profits to producers whilst building processing infrastructure and providing training that serves entire communities.

The "Nimbus" project showcases this philosophy, with the team at Raw Material distributing Rosado (née Pink Bourbon) seedlings from their El Fénix farm to smallholder families with whom they work with at their Jamaica Processing Station in Villamaría.

These producers sell cherries to the station for onwards processing, including using value-addition steps such as anoxic protocols, allowing Raw Material to create large volumes of these coffees with consistent quality, and returning a higher premium to the producers involved in the project. It's this production at scale that allows Raw Material to create the volumes required for decaffeination, as there is a minimum size of 60 bags of raw coffee for the process to occur.

After processing and drying, the coffee is milled and travels to Descafecol in Manizales for in-country decaffeination using ethyl acetate derived as a natural by-product of sugarcane fermentation. The EA process steams coffee to open cellular pores in the green coffee before extraction over 8 hours using the ethyl acetate to selectively remove caffeine, preserving over 95% of original volatile compounds whilst achieving 97-98% caffeine removal.

Descafecol currently operates at approximately 75% capacity, creating significant bottlenecks as speciality decaf demand increases, which is why we've seen (and have purchased) increasingly large amounts of coffee decaffeinated using the same process in Germany. We've booked out 6 months of supply from the producers at Villamaría over 2 lots, continuing our purchasing relationship.

- Choosing a selection results in a full page refresh.

- Opens in a new window.